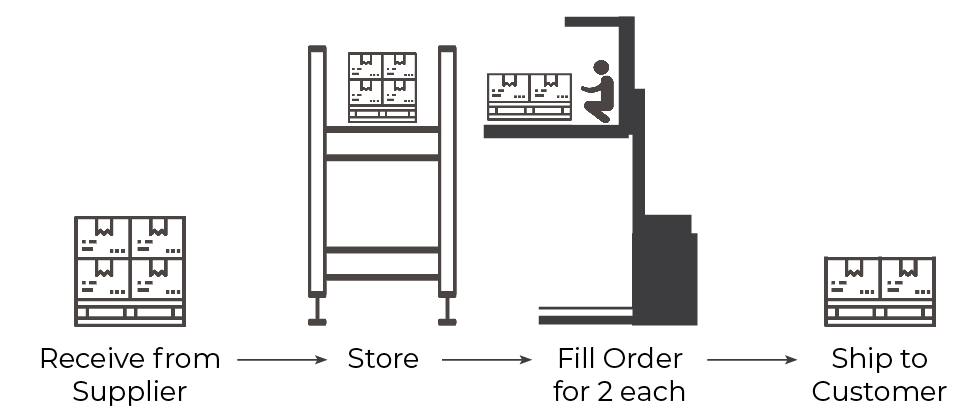

We traditionally store items the same way in which we receive them from a supplier. For example, if we receive 4 large boxes on one pallet, we maintain this structure when storing the items. When it comes time to fill an order of 2 boxes, an employee on a vehicle must go to the location, lift 2 of the 4 drums onto his or her vehicle, and then proceed to package and ship this order.

There are 2 main challenges with this approach: 1) In order to retrieve the drums, an employee is harnessed to a vehicle that is 30+ feet off the ground. The employee then has to separate two individual drums from the remainder of the packaged drums, which requires heavy lifting of 100+ lbs without much support. 2) We are completing more time consuming work during the most time-sensitive period, after a customer has placed their order, within our operational flow.

Goal: How do we create a storage to shipping flow that is more ergonomic for warehouse employees and shifts the bulk of the work to earlier in the process?

In order to understand the details of the end-to-end fulfillment process, I interviewed warehouse vehicle drivers, observed the operation over the course of a few weeks, and went on live vehicle "ride-alongs" to witness pain points within the process. I coupled qualitative research methods with quantitative data analysis to quantify how many times these pain-points occurred.

I observed the end-to-end fulfillment process and interviewed employees during each stage. I learned which items were tougher to lift while on a vehicle and what constraints drivers faced in the process.

I spent a few days riding along on the vehicle as drivers completed their fills. I was able to witness the ergonomics behind filling individually while on a vehicle and get a better sense of how much weight drivers lift per day.

I analyzed months of data to identify the top 10 heaviest items whose storage arrangement did not match how we actually sent the items to customers.

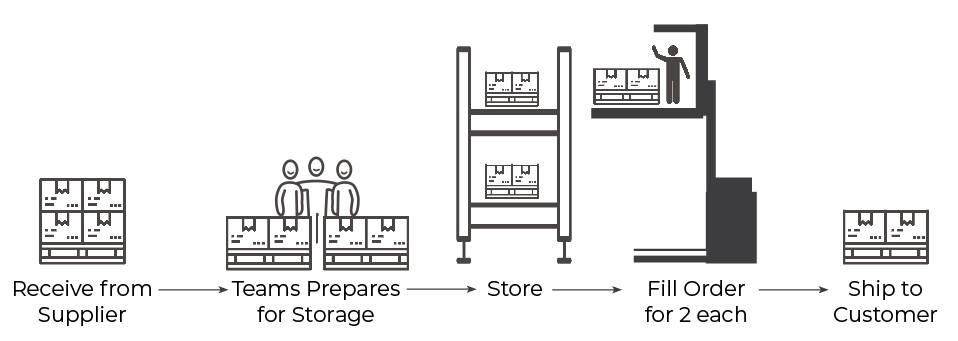

I gathered a team of participants within each stage of the process to test how the new flow would work. Team consisted of employees in the receiving, filling, and shipping department along with employees within our system development and coding teams to make back-end adjustments to our process. We began testing with large drums that would benefit the most from the new process.

Each morning when we received a supplier receipt, we would gather a team of individuals to break this down from 4 each to 2 orders of 2 each. For the pilot test, employees came in early on over-time to work out any procedural issues. A/B Testing helped identify exactly how much work we were shifting to earlier in the process and how many people we would need during this step.

Throughout the process, I gathered feedback from all employees involved in testing. The drivers loved the new process and felt much safer about not transferring as many items while in the air. The employees participating in team lifts felt the additional work we were now moving to earlier in the process did not greatly impact them, given they had both the people and the time to do this.

During this process, we discovered slight hiccups around staffing needs as well as space constraints within our warehouse. The downside of storing as we ship is that we now require double the space to store these items. During our iterations, we found a balance between how many orders we can prepare in advance based on the amount of space we had available to us.